INTRODUCTION

This case study delves into the implementation of Elasto-Valve Rubber Products 12” EVR Series 1100 pinch valves at Boroo Gold Mine, aimed at optimizing operational efficiency in tailings processing. The study explores the challenges faced by Boroo Mine, the unique advantages offered by EVR pinch valves, and the favourable outcomes achieved through their adoption.

Background

Situated in Northern Mongolia, approximately 110 km (70 mi) west-northwest of the capital Ulaanbaatar in Bayangol, Boroo Gold Mine has served as a traditional open-pit gold mining site. Commencing commercial production in March 2004, the mine yielded over 1.5 million ounces (46 tons) of gold by the end of 2010. As Mongolia’s inaugural hard-rock gold mine and a significant foreign investment, Boroo Mine contributed substantially to the country’s GDP growth, estimated at 5–7%.

CHALLENGE

Effective tailings management has long been a risk management focus in the mining industry. In mining, tailings refer to the residual materials remaining after separating economically valuable minerals from the ore’s non-profitable fraction (gangue). Tailings dams, responsible for containing these waste materials, pose operational complexities.

Apart from waste material storage, tailings dams experience substantial inflows of water. These inflows result from the water-rich slurry used to pump waste into the dams and the impact of rainfall, leading to significant and fluctuating water levels. Additionally, the chemical composition of the waste in tailings dams can pose environmental and human health risks, necessitating strict adherence to safety and environmental regulations to prevent the release of tailings waste beyond the dam’s confines.

SOLUTION

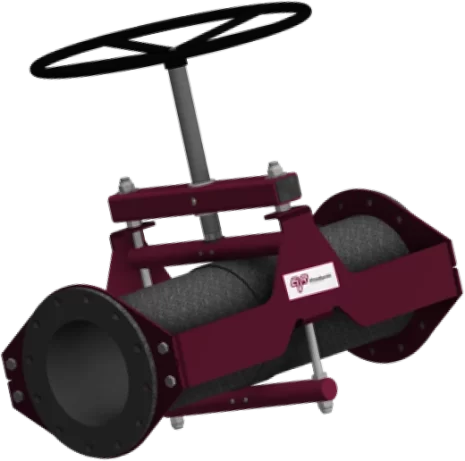

In 2005, Boroo Mine made the strategic decision to implement (40) forty EVR Products 12” EVR Series 1100 pinch valves as a solution to address these challenges, resulting in valves that were installed in 2005 and are still operational today. Widely applicable in the mining, pulp and paper, waste and water treatment, food processing, and mineral processing sectors, EVR pinch valves provided several key features and benefits that made them a flawless fit for Boroo Mine’s mineral processing requirements.

The Boroo Mine demonstrates a proactive and safety-conscious approach to diligently monitoring and managing its tailings flow and storage systems. By prioritizing stringent protocols and robust practices, Boroo Mine ensures that every aspect of tailings operations adheres to the highest industry standards for safety and environmental protection. Rigorous monitoring procedures and advanced technologies are employed to continuously track and assess tailings flow, ensuring any deviations or anomalies are promptly identified and addressed.

The EVR Series 1100 pinch valves demonstrated maintenance-free operation, with the sleeve as the sole wetted part, eliminating the possibility of contaminating process materials. Both torques and flow rates remained consistent throughout valve operation, ensuring that the valves did not become locked or jammed, even when managing high flow volumes, a critical requirement for the Boroo mine.

Results

The successful implementation of EVR Products’ 12” EVR Series 1100 pinch valves at Boroo Gold Mine showcased their efficacy in enhancing operational efficiency in mineral processing. By adopting EVR pinch valves, Boroo Mine achieved improved flow control, reduced maintenance needs, and substantial cost savings. These outcomes underscore the value of EVR pinch valves as a reliable solution for the mining industry. Collaborating with EVR Products enabled Boroo Mine to effectively manage tailings risks following the highest engineering, social, and environmental standards within the mining industry.

In 2023, Elasto-Valve Rubber Products provided an additional (36) thirty-six 12” EVR Series 1100 Pinch Valves to Boroo Mines for the tailings dam project.

Conclusion

The case study highlights the transformative impact of Elasto-Valve Rubber Products 12” EVR Series 1100 pinch valves on the operational efficiency of tailings processing at Boroo Gold Mine. By embracing these valves, Boroo Mine overcame various challenges associated with tailings management and achieved enhanced flow control, minimized maintenance requirements, and significant cost savings. This successful partnership between EVR Products and Boroo Mine serves as a testament to the effectiveness and reliability of EVR pinch valves in the mining industry, enabling the implementation of best practices in engineering, social responsibility, and environmental management.